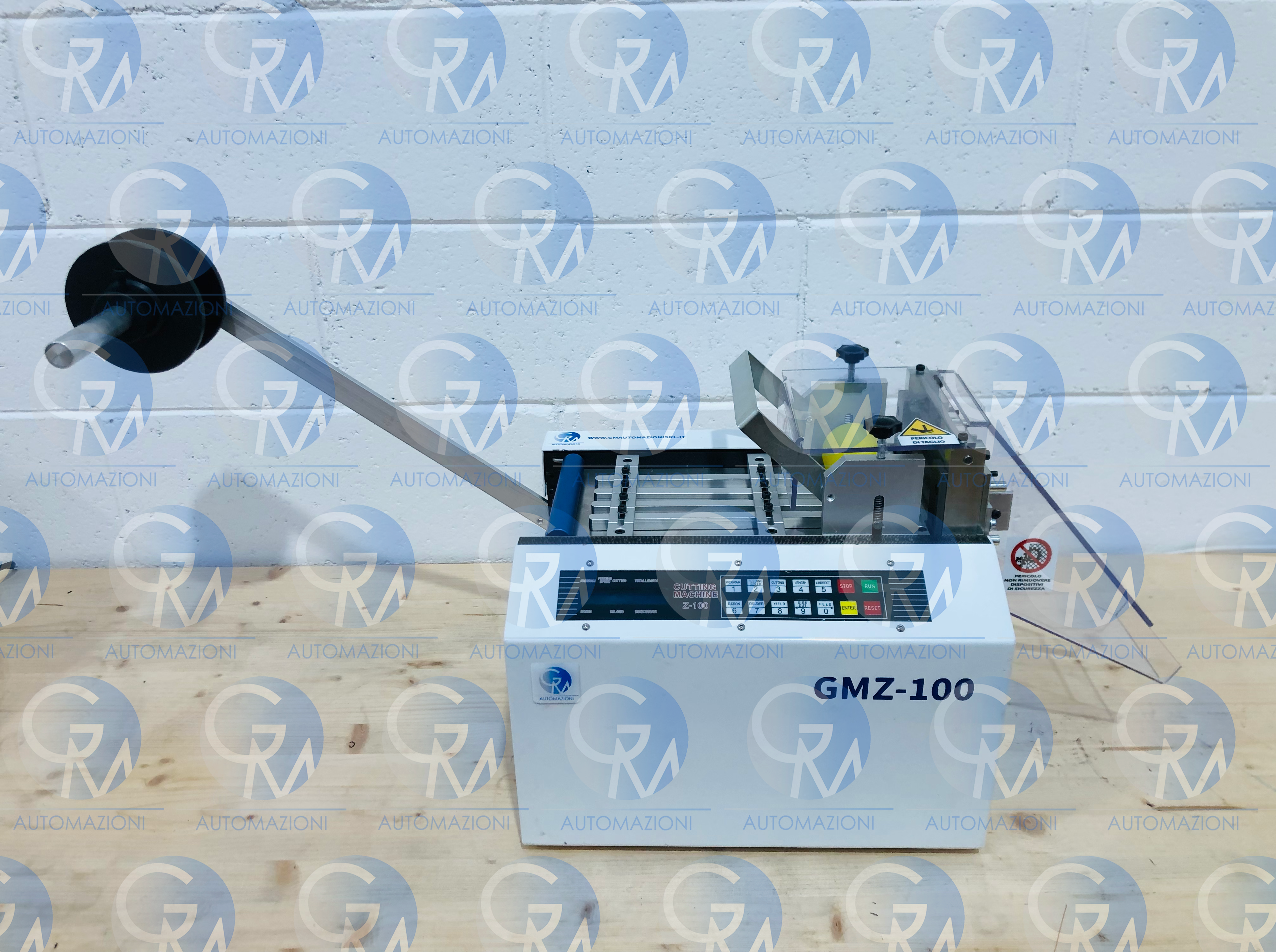

CUTTING MACHINE GM Z-100

English

Immagine:

The CUTTING MACHINE GM Z-100 is an automatic electric machine with pre-determination of the pieces and resolution of the measurements in millimeters.

The CUTTING MACHINE GM Z-100 is ideal for CUTTING TO MEASURE SOFT MATERIALS such as tubes, heat shrinkable sheaths, profiles, single core cables and flat cables also with special insulation, such as PVC, Teflon, Tefzel, silicone etc.

Extremely compact and simple to operate, it guarantees precise cuts and high productions.

The CUTTING MACHINE GM Z-100 is supplied complete with safety guards, accident prevention safety devices and instruction manual.

The machine is complete with CE certifications.

Technical features:

| ALIMENTATION | Monophase 230 V 50/60 Hz |

| PNEUMATIC ALIMENTATION | No |

| ABSORBMENT | 200 W |

| CUTTING LENGTH | 0,1 mm÷10 m |

| WORKABLE SECTIONS | 0,1÷10 mm² |

| CUTTING HEIGHT | Till to 10 mm |

| CUTTING WIDHT | Till to 95 mm |

| FEEDING | 1 Drive Rollers |

| WORKABLE CABLE | PVC-Teflon-Silicon-Tefzel-Glass-Similar |

| PRODUCTIVITY | L = 100 mm, 3.000 – 6.000 pcs/h |

| TOLERANCE | <= 0,002 xL (L=Cutting Length) |

| DISPLAY | LCD Liquid Cristal Display |

| MEMORY | 99 Programs |

| WEIGHT | 25 Kg |

| DIMENSIONS | 480x350x400 (WxDxH) |

IN ADDITION TO THE SALE OF THE EQUIPMENT GM AUTOMAZIONI IS ABLE TO PROVIDE MANY SERVICES, INCLUDING:

- WIDE RANGE OF PRODUCTS FROM OUR PRODUCTION AND THE BEST BRANDS ON THE MARKET

- CUSTOMIZATION OF EQUIPMENT AND PLANTS TAILORED TO THE CUSTOMER'S NEEDS

- DESIGN AND REALIZATION OF SPECIAL SYSTEMS

- TECHNICAL ASSISTANCE AT OUR HEADQUARTERS OR AT THE CLIENT'S HEADQUARTERS

- SPARE PARTS FOR ALL MACHINES OFFERED

- COURSES AND DEMONSTRATIONS TO USE THE EQUIPMENT BETTER

- INSTALLATION AND TRAINING OF THE STAFF EMPLOYED BY THE MACHINES

- VERIFICATION OF FEASIBILITY ACCORDING TO CUSTOMER REQUESTS

- FREE SAMPLES BY TESTING DIRECTLY ON YOUR SAMPLES

- DEMONSTRATION OF THE EQUIPMENT AT OUR HEADQUARTERS OR AT THE CLIENT'S HEADQUARTERS

- COURSES AND SEMINARS FOR IN-DEPTH INFORMATION ON THE USE OF EQUIPMENT

- SCHEDULED MAINTENANCE TO AVOID EXPENSIVE MACHINE STOP

- POSSIBILITY OF EXCHANGE: THE OLD SYSTEM CHANGES WITH A NEW AND MORE COMPETITIVE

- WE ARE SUPPLIERS OF STEEL, HARD METAL AND TITANIUM STRIPPING BLADES, MINI-APPLICATION CRIMPERS, ELECTRIC TERMINALS, PRE-INSULATED CONNECTORS, SPLICE STRIP

- WITHDRAWAL AND OVERVALUATION OF USED

- SALE OF COMPONENTS AND ACCESSORIES OF THE MAJOR BRANDS OPERATING ON THE MARKET

- POSSIBILITY TO IMPLEMENT OR MODIFY YOUR OLD PRODUCTION PLANT FOR YOUR NEW MARKET NEEDS

Categoria prodotto:

Immagine 2:

Immagine 3:

Immagine 4: