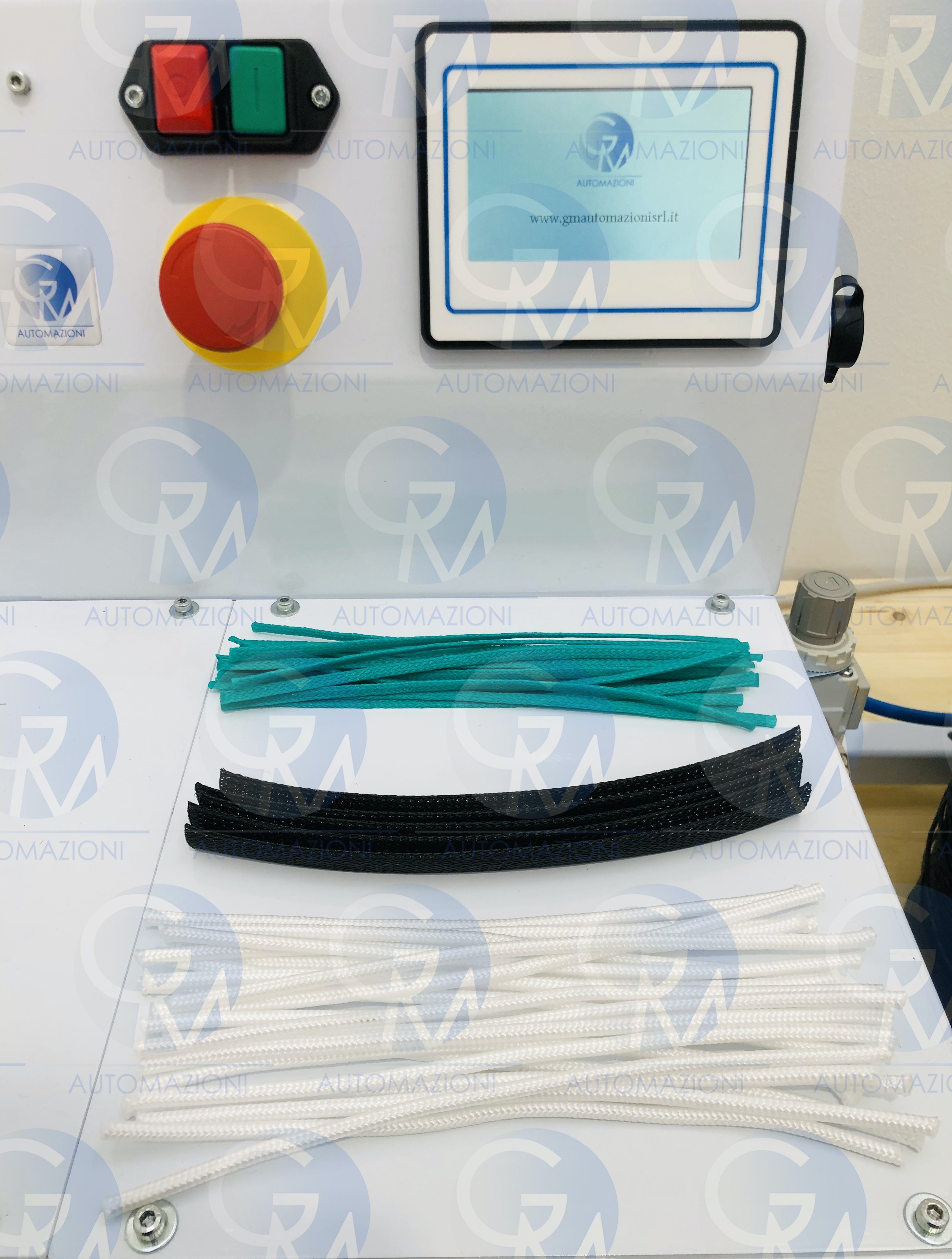

MÁQUINA DE CORTE EN CALIENTE GM70

Spanish

Immagine:

Dependiendo de la configuración, la MÁQUINA DE CORTE EN CALIENTE GM70 puede cortar:

- Frío con hojas de tijera de acero templado y autoafilamiento con luz de corte máxima de 70 mm;

- Caliente con una cuchilla calentada por resistencia eléctrica de baja tensión y el corte de MÁQUINA DE CORTE EN CALIENTE GM70 se realiza mediante termoendurecimiento (adecuado solo para materiales sintéticos) con una luz de corte de 70 mm y se puede equipar con un dispositivo de corte automático inclinado;

- Con ambos grupos de corte, que se pueden usar por separado, se pueden seleccionar directamente del programador electrónico.

Technical features:

| ALIMENTATION | Monophase 230 V 50/60 Hz |

| PNEUMATIC ALIMENTATION | 6 Bar |

| ABSORBMENT | 800 W Hot Cut/400 W Cold Cut |

| CUTTING LENGTH | 0,1 mm÷100 m |

| WORKABLE SECTIONS | Not Definable |

| CUTTING HEIGHT | Not Definable |

| CUTTING WIDHT | Till to 70 mm |

| FEEDING | 1 Drive Rollers |

| WORKABLE CABLE | Fabrics and Plastic Materials |

| PRODUCTIVITY | L = 100 mm, 3.000 – 6.000 pcs/h |

| TOLERANCE | <= 0,002 xL (L=Cutting Length) |

| DISPLAY | Touch Screen LCD Liquid Cristal Display |

| MEMORY | 100 Programs |

| WEIGHT | 46 Kg |

| DIMENSIONS | 540x560x570 (WxDxH) |

IN ADDITION TO THE SALE OF THE EQUIPMENT GM AUTOMAZIONI IS ABLE TO PROVIDE MANY SERVICES, INCLUDING:

- WIDE RANGE OF PRODUCTS FROM OUR PRODUCTION AND THE BEST BRANDS ON THE MARKET

- CUSTOMIZATION OF EQUIPMENT AND PLANTS TAILORED TO THE CUSTOMER'S NEEDS

- DESIGN AND REALIZATION OF SPECIAL SYSTEMS

- TECHNICAL ASSISTANCE AT OUR HEADQUARTERS OR AT THE CLIENT'S HEADQUARTERS

- SPARE PARTS FOR ALL MACHINES OFFERED

- COURSES AND DEMONSTRATIONS TO USE THE EQUIPMENT BETTER

- INSTALLATION AND TRAINING OF THE STAFF EMPLOYED BY THE MACHINES

- VERIFICATION OF FEASIBILITY ACCORDING TO CUSTOMER REQUESTS

- FREE SAMPLES BY TESTING DIRECTLY ON YOUR SAMPLES

- DEMONSTRATION OF THE EQUIPMENT AT OUR HEADQUARTERS OR AT THE CLIENT'S HEADQUARTERS

- COURSES AND SEMINARS FOR IN-DEPTH INFORMATION ON THE USE OF EQUIPMENT

- SCHEDULED MAINTENANCE TO AVOID EXPENSIVE MACHINE STOP

- POSSIBILITY OF EXCHANGE: THE OLD SYSTEM CHANGES WITH A NEW AND MORE COMPETITIVE

- WE ARE SUPPLIERS OF STEEL, HARD METAL AND TITANIUM STRIPPING BLADES, MINI-APPLICATION CRIMPERS, ELECTRIC TERMINALS, PRE-INSULATED CONNECTORS, SPLICE STRIP

- WITHDRAWAL AND OVERVALUATION OF USED

- SALE OF COMPONENTS AND ACCESSORIES OF THE MAJOR BRANDS OPERATING ON THE MARKET

- POSSIBILITY TO IMPLEMENT OR MODIFY YOUR OLD PRODUCTION PLANT FOR YOUR NEW MARKET NEEDS

Categoria prodotto:

Immagine 2:

Immagine 3:

Immagine 4:

Immagine 6: